POLYASPARTIC GARAGE FLOOR Coatings

a longer lasting garage floor

Polyaspartic Floor Coatings

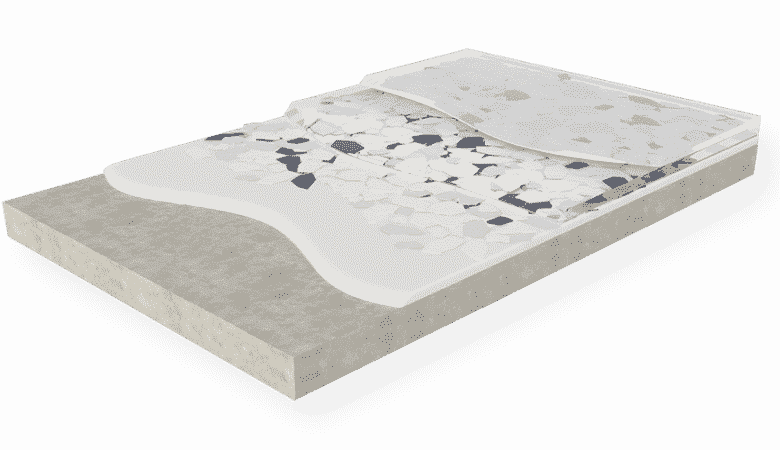

Polyaspartic and polyureas are within the same family of floor coatings, which is why they are often coupled together when people talk about them. They are one of the best concrete coatings available on the market, with many benefits.

These floor coatings are no DIY project, though – you need to hire a professional in order to have polyurea and polyaspartic floor coatings installed.

This is in part due to how quickly polyurea and polyaspartic coatings cure. If you aren’t an experienced technician, you could inadvertently ruin your floor due to its rapid curing time.

Done professionally, though, polyurea and polyaspartic coatings will ensure you can use your surfaces again within a day, and keep your floors beautiful and in good condition for years to come.

What’s The Difference Between Polyurea And Polyaspartic?

Polyurea is a subgroup of polyurethane, and is a two-component product. The two components mixed together result in a mixture that hardens very quickly, within minutes, which is why it takes professionals to apply, in addition to the specialized equipment required for the application process.

Polyaspartic is polyurea, but polyurea that hardens at a slower rate. This allows for garage floor coating experts to ensure that your floor is covered evenly before it hardens.

Polyurea is better for indoor applications, given the fact that it isn’t UV resistant. Polyaspartics are the best available option for outdoor applications, since they are UV resistant, extremely durable, and their slick-ness can be lessened by having a grit additive mixed into the top coat for slip resistance.

Why Choose Polyaspartic Floor Coatings?

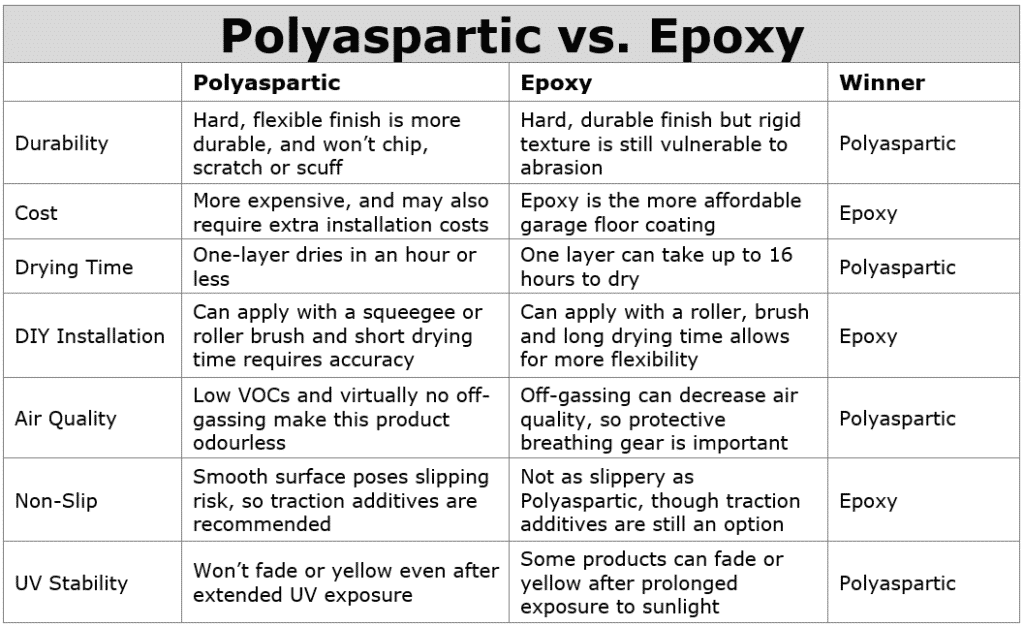

Professionals recommend polyurea and polyaspartic floor coatings because they are up to six times stronger than epoxy floor coatings. They can withstand more damage, can be used inside and outside, last longer, and can be customized to look how you want them too.

Why You Should Use a Professional?

If you can DIY epoxy floor coatings, you may wonder why you can’t do the same thing for polyurea and polyaspartic floor coatings. This is because these products have very limited working time, meaning that you need to know exactly what you’re doing in order to ensure that they’re applied properly.

The preparation process requires heavy duty, professional equipment in order to grind the concrete down so that the polyurea and polyaspartic coatings can adhere correctly. The process of grinding concrete in order to prepare it can result in a lot of dust, which professionals use vacuums connected to the equipment in order to contain. They can also have fumes, depending on the manufacturer, which can result in eye irritation, headaches, and coughing.

You can’t DIY these floor coatings because they require professional expertise in order to ensure that everything is prepared, applied, and finished properly, so that your floor coating looks and functions how it should.

Pros

We recommend these floor coatings because of their many benefits. Some of the advantages to these coatings include:

- They’re chemical and stain resistant.

- They’re resistant to high abrasions.

- They don’t chip like epoxy.

- They can be applied in the cold.

- They’re stronger than epoxy.

- They provide a paint chip or quartz look.

- They’re quick to apply and cure.

- They’re UV stable.

- There’s no hot tire pickup.

Cons

As with anything, polyurea and polyaspartic floor coatings do come with disadvantages too. For some, the fact that you must hire a professional for them is a disadvantage in and of itself. Some of the other cons include:

- Depending on the manufacturer, they can have strong fumes and VOC’s.

- They can get slick with snow and water.

If you’re looking to install floor coatings, make sure you’re hiring a professional for the job. Our polyurea and polyaspartic floor coatings will transform your floors into something beautiful that also keeps them in good condition for years to come. To learn more about floor coatings, contact My Garage Floor Guys. We’ll help you decide on the best options for you.

Polyaspartic Garage Floor Coatings FAQ

Polyaspartic garage floor coating is a type of high-performance coating made from polyaspartic polyurea. It offers durability, chemical resistance, and quick curing times compared to traditional epoxy coatings.

Polyaspartic coatings offer benefits such as rapid cure times (typically in a single day), excellent durability, resistance to chemicals and abrasions, UV stability, and a glossy finish.

Surface preparation involves cleaning the floor thoroughly, repairing any damage or cracks, and ensuring the surface is free from contaminants for proper adhesion.

Polyaspartic coatings can adhere well to concrete, cement, and other suitable surfaces. Proper surface preparation is crucial for a successful application.

With proper care and maintenance, a polyaspartic coating can last around 20 years.

Yes, you can choose from a variety of colors, finishes, and even add decorative elements like flakes or metallic pigments for a unique look.

Polyaspartic coatings have a rapid cure time, usually within a day. This means you can return your garage to normal use quickly.

You can typically use your garage within 24 hours of the application of polyaspartic coating, making it a convenient option.

Yes, polyaspartic coatings are known for their exceptional resistance to chemicals, oils, and stains, making them ideal for garages.

Regular sweeping and mopping with a mild detergent should keep your floor looking great. Avoid harsh chemicals that could damage the coating.

Polyaspartic coatings can be slippery when wet. Incorporating an anti-slip additive into the topcoat can improve traction.

Polyaspartic coatings are known for their temperature tolerance and can be applied in various climates, including those with temperature fluctuations.

Unlike some coatings, polyaspartic coatings can be applied to slightly damp surfaces, making them more versatile in humid conditions.

Polyaspartic coatings are typically applied in a single layer due to their quick cure time. Consult with professionals for specific recommendations.

Polyaspartic coatings can be removed using mechanical methods, but it’s a labor-intensive process.

Ready To Transform Your Garage?